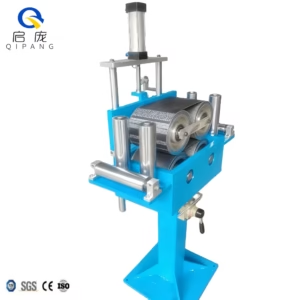

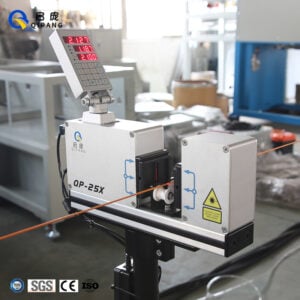

Shanghai Qipang’s core product line includes: High Speed High-Precision Laser Diameter Gauge, Non-contact Large Display Diameter Measurement Tool, Single Axis/Double Axis Handheld Laser Scanning Diameter Machine, Spark Machine, Meter Counter, Powder Passing Machine, Preheater Machine, and a comprehensive range of related cable manufacturing equipment designed to meet diverse production needs. Suitable for Round Wire, Flat Wire, Electronic Wires, Power Cables, Braided Wires, Ropes, Aerospace Wires, Steel Wire Ropes, Transparent Tube, Medical Tube, Rubber Tube, Extruder, Drawing Machine, and a series of related cable detection equipment.

- High-speed brushless motor scanning;

- Multifaceted high-precision standard prism;

- High-speed dual DSP processing chip;

- Excellent signal quality, high precision, high resolution;

- Has the ability to measure diameter, position, beating, and multiple roots;

- Conventional body, micro body, transparent body, allotrope measurement;

- RS485, TCP/IP, PROFINET communication options;

Laser diameter gauge parameter

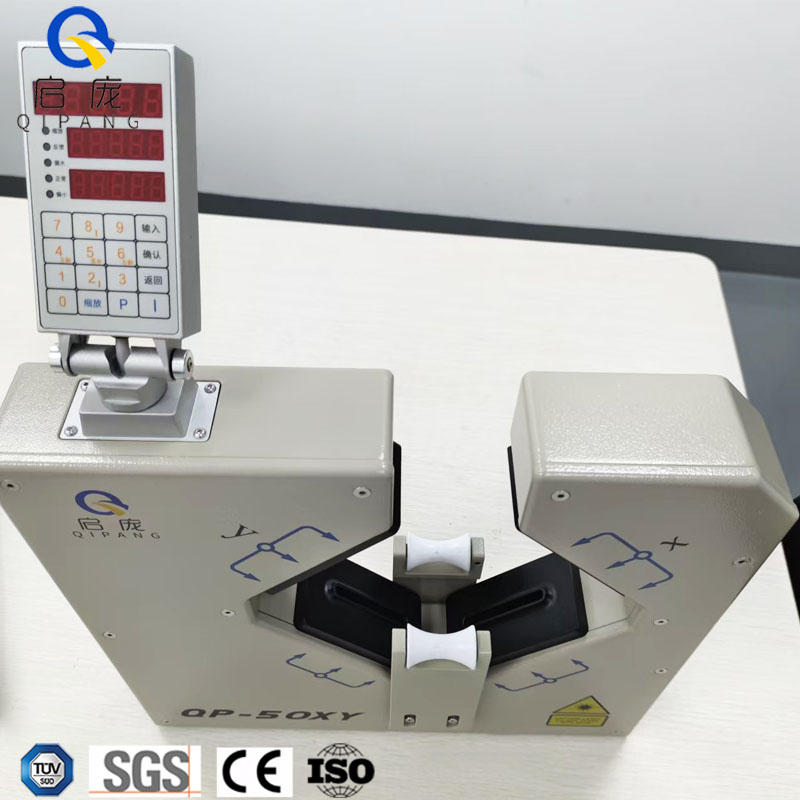

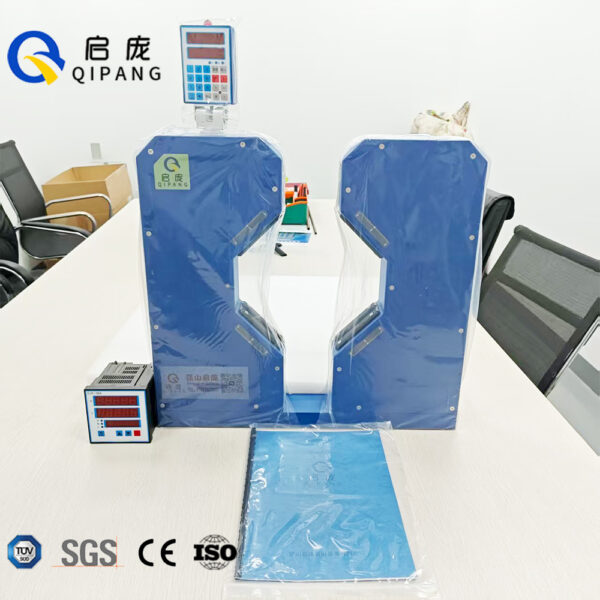

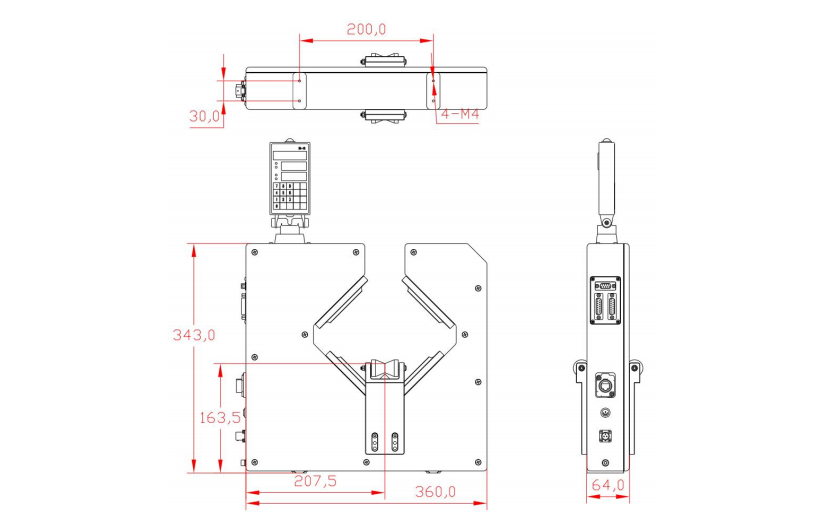

| model | 3XY | 25XY | 50XY | 70XY | 120XY | 170XY |

|---|---|---|---|---|---|---|

| Measuring axis number | dual aixs | dual aixs | dual aixs | dual aixs | dual aixs | dual aixs |

| Scanning speed of diameter gauge | 1400 times/second | 1400 times/second | 1400 times/second | 1400 times/second | 1400 times/second | 1400 times/second |

| Resolution | 0.001mm | 0.001mm | 0.001mm | 0.001mm | 0.001mm | 0.001mm |

| Power supply voltage | AC220V+10% 50HZ | AC220V+10% 50HZ | AC220V+10% 50HZ | AC220V+10% 50HZ | AC220V+10% 50HZ | AC220V+10% 50HZ |

| Optional accessories | Bracket, serial line,remote controller, remote display | Bracket, serial line,remote controller, remote display | Bracket, serial line,remote controller, remote display | Bracket, serial line,remote controller, remote display | Bracket, serial line,remote controller, remote display | Bracket, serial line,remote controller, remote display |

| weight | 5kg | 4.5kg | 8.5kg | 16KG | 27kg | 30kg |

Common measurement errors and faults of laser diameter gauges mainly include the following:

Environmental factors: Environmental changes such as temperature, humidity and air quality will affect the propagation path and stability of the laser, resulting in measurement errors.

Laser light source stability: The fluctuation and attenuation of the light source will affect the measurement accuracy. An unstable light source or insufficient power may cause inaccurate readings.

Surface characteristics of the measured object: The reflective characteristics, color and roughness of the measured object’s surface will affect the intensity and accuracy of the laser reflection echo.

Alignment error: Failure of the laser beam to accurately align with the center of the measured object or measurement angle deviation will result in measurement data deviation.

Electronic interference: Interference from surrounding electronic equipment may affect the circuit operation of the laser measuring instrument, resulting in incorrect data readings.

Calibration problems: Equipment not calibrated regularly or inaccurately will cause measurement errors.

Mechanical vibration: The vibration of the diameter measuring instrument or the object being measured will affect the stability and accuracy of the measurement results.

The impact of these errors and faults can be effectively reduced by regularly maintaining and calibrating the laser diameter gauge and improving the measurement environment.

_副本-300x300.jpg)