Shanghai Qipang specializes in the production of fixed-length winding and cutting lines for cables. It can provide professional solutions based on the different sizes of reels, types of cables, and the varying required lengths as specified by customers.

Our cable fixed-length winding and cutting production line integrates advanced winding technology with precise cutting systems. It can smoothly and rapidly wind various types and specifications of cables from standard large reels onto user-specified small reels, and precisely cut them according to the preset meters, significantly enhancing the automation level and production efficiency of the subsequent cable processing steps.

Cable Winding and Cutting Line Parameter

| Model | QP460 |

|---|---|

| wire diameter | 2-16mm cable |

| Pay off reel size | 0D630/800mm |

| Pay off method | Automatic tension release withor without shaft |

| Take up traverse type | rolling ring drive/PLC servo |

| Take up load capacity | 200KG single shaft |

| Line method | Automatic wiring |

| Machine Speed | 0-500 rpm, Customizable |

| Wire tie outer diameter | φ310/400/450mm |

| Number of cable tie slots | 3 slots |

| Motor Power | 2.2/4KW+ Reducer Motor |

| Wire tie inner diameter | φ140/160/180mm |

| Wire tie height | 30-200mm, Customizable |

| Machine Color | RAL5015 blue, Customizable |

| Output per shift | Around 700 coil(7 hours) |

| power supply | 380V 50HZ three-phase or Customizable |

Cable Winding and Cutting Line Feature

Coiling System:

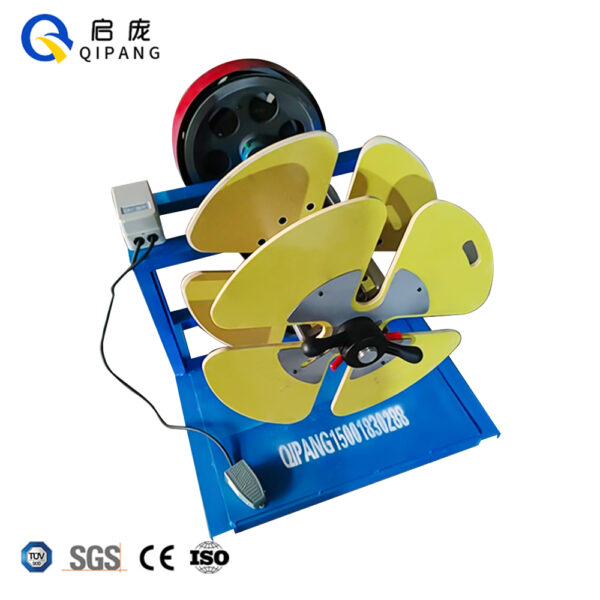

There are various types of winding machines available, including cantilever type or shaft type take up machines. The machine size can be customized to meet different types and sizes of spools for customers. The wiring section can choose either rolling ring drive wiring device or servo plc wiring. The wiring width can be adjusted according to the width of the spool.

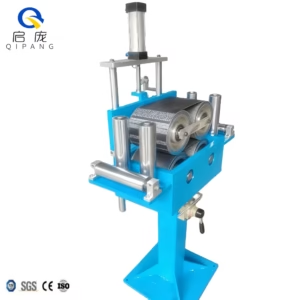

Fixed-length Cutting System

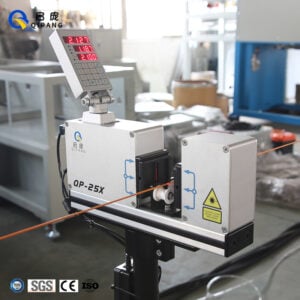

Precision measurement: The meter counter equipped with high-precision encoders ensures the accuracy of the cable winding length, with an error controlled within 1/1000 to 1/3000.

Fast cutting: Utilizing efficient cutting devices (such as pneumatic or hydraulic cutting based on the cable material), the cutting surface is smooth and free of burrs, and the speed is perfectly matched with the winding system.

Flexible setting: The operation is simple, and different winding lengths and quantities can be quickly set according to production requirements.

Active Pay Offf Machine

The pay off machine is driven by an independent motor instead of being pulled passively. The machine is equipped with a storage rack to monitor the tension of the cable in real time and dynamically adjust the spooling speed to ensure constant tension and prevent the cable from being pulled too thin, stretched, or causing the spool to become untwisted.

Whether it is power cables, communication cables, control cables or other special types of cables, our production line can provide stable and reliable performance. It is an ideal choice for wire and cable manufacturers, cable distributors and related processing enterprises. It not only simplifies the production process, reduces errors and labor intensity caused by human intervention, but also ensures the consistency of product quality, helping you stand out in the fierce market competition.

_副本-300x300.jpg)