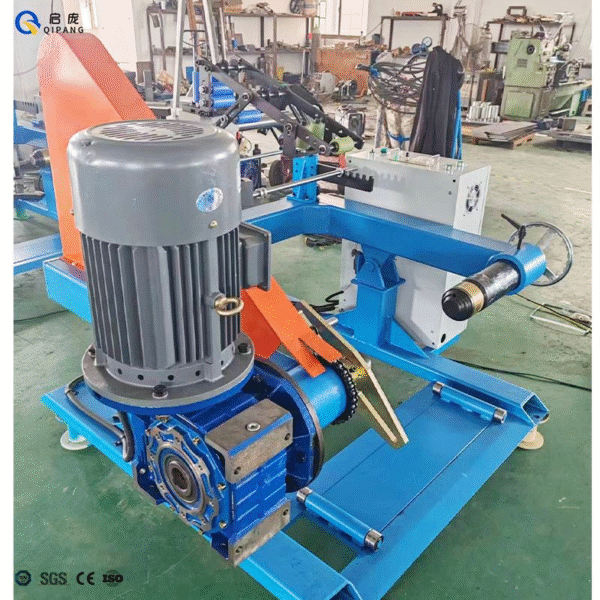

Gantry type cable pay off and take up machine has the characteristics of excellent design, well processing and complete functions. The whole machine consists of two ground beams with roller, two columns and sleeve telescopic beams and electrical control system.

| Model | QP2000 | QP2500 | QP3150 |

|---|---|---|---|

| Suitable Material Diameter | 3-80mm | 3-100MM | 3-100MM |

| Clamping motor: | BLD10-11-1.1KW | BLD10-11-1.1KW | BWY10-23-1.1KW |

| Reel Lifting Motor | BLY11-29-1.5KW | BLY11-29-1.5KW | BLY10-29-2.2KW |

| Cable motor | 1.5KW servo motor | 1.5KW servo motor | BWEY121-595-1.5KW frequency conversion |

| Main motor for take-up machine | AC variable frequency motor 7.5KW | AC variable frequency motor 11KW | AC variable frequency motor 15KW |

| Power supply | 380V, 3-phase, 50HZ Or customize | 380V, 3-phase, 50HZ Or customize | 380V, 3-phase, 50HZ Or customize |

| Equipment color | RAL5015 blue | RAL5015 blue | RAL5015 blue |

Use:

This machine is suitable for the extrusion, cross linking, cable, winding of various wire, cable and communication cable and cable manufacturing equipment, etc.

Key Features and Characteristics:

-

Strong Structure:The gantry frame provides a stable and robust platform for handling large and heavy reels.

-

Large Reel Capacity:Suitable for reels with flange diameters ranging from 1000mm to 31000mm and reel weights up to 18T

-

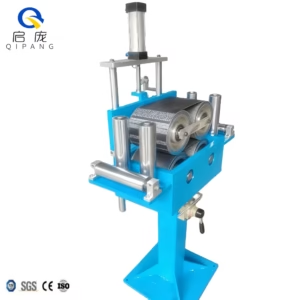

Reel Handling:Reels are placed on pintles (shafts) and can be loaded/unloaded with the help of pintle adaptors and motors for lifting and lowering.

-

Traversing Mechanism:A traversing unit moves the reel left and right on rails, and can be customized for front-and-back movement as well.

-

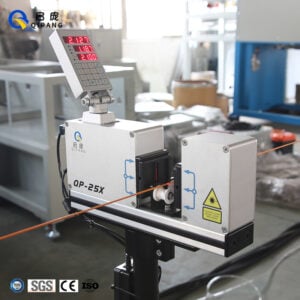

Winding Control:Winding is typically done with a motor, often using torque control, and can be adjusted for speed based on dancer or accumulator unit feedback.

-

Versatility:Can be used in various processes like extrusion, rewinding, taping, and armoring.

-

User-Friendly Controls:Equipped with electrical control cabinets, operation boxes, and control panels for easy operation and monitoring.

-

Safety Features:Include features like automatic and manual direction change, adjustable clamp force, and mechanical and electrical double protection devices.

_副本-300x300.jpg)