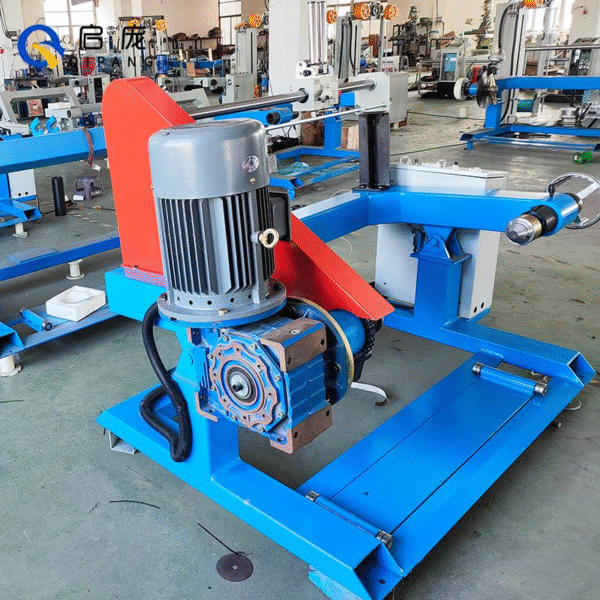

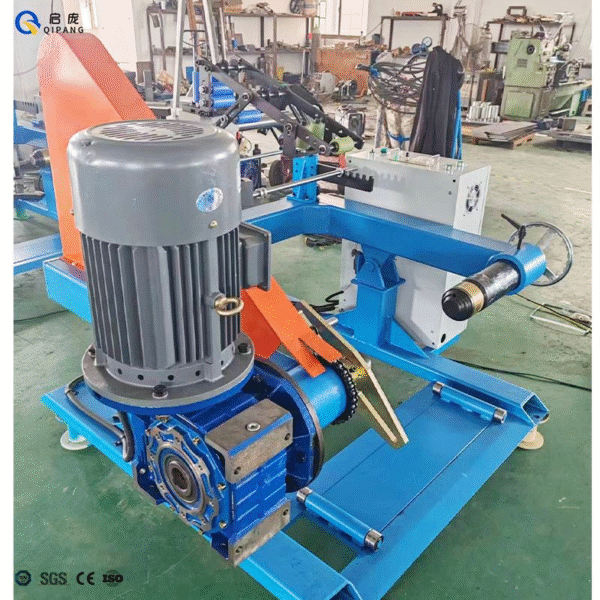

Gantry floor rail walking type, upper casing type structure, the gantry frame is made of bending and welding; the two tops of the spool are lifted and lowered by two motors through the cycloid reducer to drive the screw nut, and each top seat can be lifted and lowered independently or at the same time and is equipped with mechanical and electrical double protection devices.

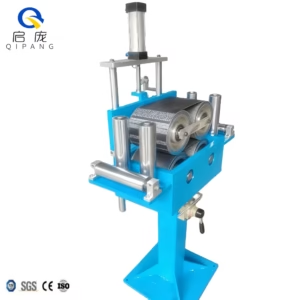

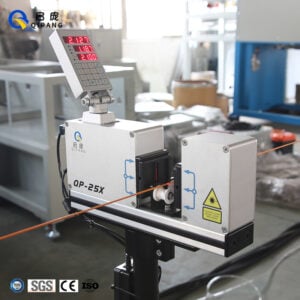

A gantry type take-up machine is a heavy-duty system designed for winding and unwinding large reels, particularly in cable and wire manufacturing. These machines feature a gantry (or bridge) structure that supports the reel, allowing for movement along rails and offering stability for handling substantial loads. They are commonly used in conjunction with pay-off stands in continuous production lines for processes like extrusion, stranding, and armoring.

| Model | QP2000 | QP2500 | QP3150 |

|---|---|---|---|

| Suitable Material Diameter | 3-80mm | 3-100MM | 3-100MM |

| Clamping motor: | BLD10-11-1.1KW | BLD10-11-1.1KW | BWY10-23-1.1KW |

| Reel Lifting Motor | BLY11-29-1.5KW | BLY11-29-1.5KW | BLY10-29-2.2KW |

| Cable motor | 1.5KW servo motor | 1.5KW servo motor | BWEY121-595-1.5KW frequency conversion |

| Main motor for take-up machine | AC variable frequency motor 7.5KW | AC variable frequency motor 11KW | AC variable frequency motor 15KW |

| Power supply | 380V, 3-phase, 50HZ Or customize | 380V, 3-phase, 50HZ Or customize | 380V, 3-phase, 50HZ Or customize |

| Equipment color | RAL5015 blue | RAL5015 blue | RAL5015 blue |

-

Cable Manufacturing:Used extensively in cable manufacturing lines for handling the take-up and pay-off of various types of cables.

-

Wire Manufacturing:Can be used in wire production lines for handling the take-up of different wire types.

-

Continuous Production:Often employed in continuous production lines where a constant supply of material is needed.

-

Rewinding and Processing:Suitable for rewinding processes and other cable processing operations.Benefits:

- Increased Efficiency: Facilitates efficient reel handling and winding, especially for large reels.

- Reduced Labor Costs: Automated features can reduce manual labor requirements.

- Improved Production: Contributes to smoother and more reliable continuous production processes.

- Enhanced Safety: Safety features minimize risks associated with handling heavy reels.

- Customization: Can be customized to specific requirements, including reel sizes, winding speeds, and tension control.

- Increased Efficiency: Facilitates efficient reel handling and winding, especially for large reels.

_副本-300x300.jpg)