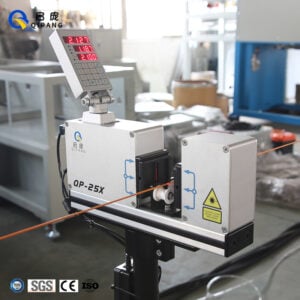

The spark machine is a reliable quality inspection tool for various wires and cables. A precision instrument designed for online detection of pinholes, broken skin, bare copper, and other poor insulation points on the conductor insulation layer. This machine uses high-frequency (3KHz) high-voltage electrode heads to replace traditional (50, 60Hz) power-frequency high-voltage electrode heads. The electrode head size can be selected as a 50/120mm beaded contact type that considerably reduces installation size and significantly improves detection speed (1200-2400m/min). The machine is a highly reliable quality control tool with integrated practical patents in one body, making it easier to operate and more durable.

| Parameters | Values |

|---|---|

| Power supply voltage | AC220V/250V±15% |

| Power frequency | 50±2Hz |

| Input power | 120VA |

| Ambient temperature | -10~45℃ |

| Relative humidity | less than 85% (no condensation) |

| Detection voltage | AC 0-10-15KV. Please specify when ordering |

| Breakdown sensitivity | I=600±50uA, t≤0.005s |

| The maximum moving speed of the inspected line | 1000/min |

| Output frequency | 2.5~3.5KHz |

| The maximum outer diameter of the tested cable | Φ5mm |

| Center height | 850-1050MM adjustable |

| Size | 615*405*485 (excluding packaging) |

| Weight | 22KG |

Applications:

The Sine Wave Spark Tester is an excellent quality inspection tool suitable for various wire and cable industries. It benefits occasions with wire diameters ≤ 5mm, wire speeds ≥ 200m/min, and strict quality inspection requirements.

Breakdown Indication:

- Automatic mode: A breakdown will generate a counting sound and light alarm contact signal action, automatically reset to continue high-voltage detection status.

- Manual mode: After the breakdown counting, the audible and visual alarm contact signal is permanently sustained and controlled. The output and the high-voltage detection status can only continue by pressing the reset button manually.

Safety Interlock

When the protective cover of the electrode box is opened, the high voltage is automatically cut off to ensure the operator’s safety. At the same time, the external contact signal can control the low voltage circuit to make the high voltage on and off (for example, if the wind stops, the high voltage will also stop, and if the spark fails, the winding will also stop. stop).

Measuring Principle:

The QP-15AC High-Frequency Cable Spark Test Machine uses high-frequency (3KHz) high-voltage electrode heads to replace traditional (50, 60Hz) power frequency high-voltage electrode heads. This system detects the defects of the conductor’s outer covering without harming the electrical conductor’s inner shell. The machine quickly detects the poor insulation points on the conductor insulation layer through high-frequency sparks and generates an alarm signal.

FAQs:

1. What is the QP-15AC High-Frequency Cable Spark Test Machine’s maximum moving speed of the inspected line?

Ans: The maximum moving speed of the inspected line is 1000/min.

2. What is the maximum outer diameter of the tested cable?

Ans: the maximum outer diameter of the tested cable is Φ5mm.

3. Is the QP-15AC High-Frequency Cable Spark Test Machine compatible with wire diameters above 5mm?

Ans: It can be used with wire diameters above 5mm, but it may affect the detection sensitivity.

4. What is the breakdown sensitivity of the QP-15AC High-Frequency Cable Spark Test Machine?

Ans: The breakdown sensitivity is I=600±50uA, t≤0.005s.

5. What is the size and weight of the QP-15AC High-Frequency Cable Spark Test Machine?

Ans: The size of the machine is 315* 305* 245mm (excluding packaging), and it weighs approximately 9 kg.

_副本-300x300.jpg)