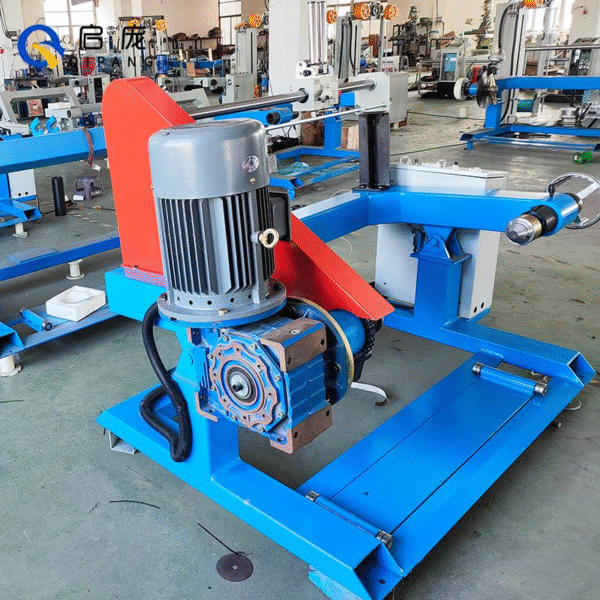

The Optical Fiber Winder Cable Take up Machine is a device that uses a servo control system and is driven by a high-precision servo motor to neatly wind the fiber optic cable into a reel. Its core function is to ensure that the fiber optic cable maintains uniform tension and neat arrangement during the winding process, and to prevent the fiber from being damaged due to excessive bending or uneven winding.

Working Principle

The working principle of the optical fiber servo winder mainly includes the following key steps:

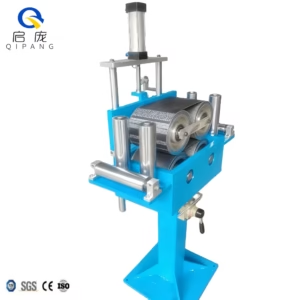

Paying off: The wire storage type automatic tension pay-off frame is used to ensure that the wire has uniform tension during the paying off process to avoid damage to the optical fiber due to uneven tension.

Reeling and arranging: The servo motor drives the winding roller to rotate, and cooperates with the automatic arranging device to neatly wind the optical fiber onto the take-up reel. The servo control system can accurately control the winding speed and tension to ensure that the optical fiber is arranged tightly and evenly.

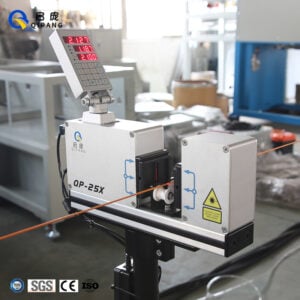

Tension control: The equipment is equipped with a high-precision tension control system, which realizes automatic adjustment through the servo motor and PLC (programmable logic controller) to avoid loose or excessive stretching of the optical fiber during the winding process.

Metering and control: The built-in electronic meter device can accurately measure the length of the optical fiber and automatically stop when the set length is reached to avoid waste

_副本-300x300.jpg)