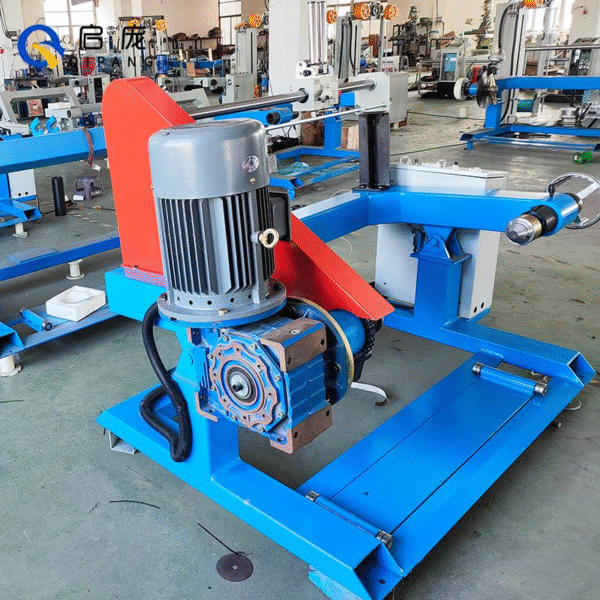

Portal-type cantilever Electric rewinding machine refers to a specific type of manufacturing equipment or process used to take wire or cable from its original spool or reel and transfer it onto a new spool or reel according to specified requirements.The primary purpose is to re-package or reconfigure finished wire and cable products. This often involves changing the length of the cable roll, altering the diameter of the spool, or adapting the cable’s form for specific applications or customer needs.

| Model | QPM400 |

|---|---|

| spool size | od: ø400-ø800mm ID ø50-ø80mm |

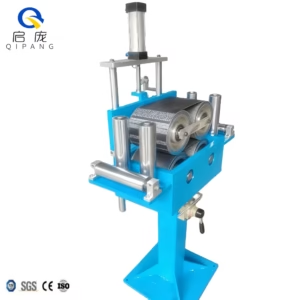

| Wire/Cable Arrangement | GP30 Rolling Ring Traverse |

| Clamping Method: | cylinder clamping |

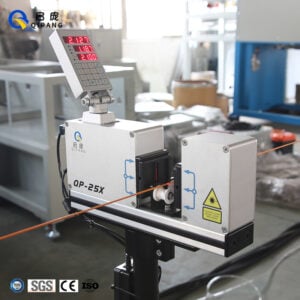

| meter counter | With alarm function, it will automatically stop when reaching the required number of meters |

| Reeling speed: | ≤ 300 revolutions per minute |

| Lifting method: | Electric lifting with electronic limit switch. |

| max load | 200kg |

| Tray installation method: | Bottom tray |

| power | 380V, 3-phase, 50HZ Or customize |

| Frequency Converter: | Use Inovance MD310 series with brake resistor and reserved tension frame speed control interface |

- Purpose & Benefits:

- Customization: Creating specific lengths or package sizes not available from the initial manufacturing run.

- Efficiency: Automating the often labor-intensive process of manually rewinding large quantities of cable.

- Damage Prevention: Using controlled tension and proper handling to protect the cable’s integrity.

- Logistics: Preparing cables for easier storage, transportation, and deployment in various industries

- Applications: These production lines are crucial in industries like automotive (for wiring harnesses), construction (for power cables), telecommunications, electronics, and renewable energy (for solar or wind power cables).

In essence, it’s a specialized setup for efficiently and safely transferring wire or cable from one spool to another, meeting specific length, spool size, or packaging requirements.

_副本-300x300.jpg)