Shanghai Qipang is a leading enterprise specializing in the research, design, manufacturing, and sales of active pay off machine. Our mission is to provide customers with efficient, stable and intelligent wire processing solutions through technological innovation. From cable pay off machines, coiling and reeling machine cable rewinding machines to other auxiliary equipment, we are dedicated to helping global customers optimize production processes, reduce operating costs and enhance product quality.

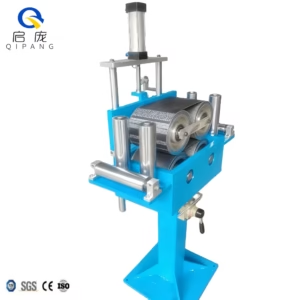

Designed for precision wire and cable processing, this Active Pay-off Machine provides powered, synchronized unwinding to ensure smooth production. Unlike passive pay-out machine, this unit actively drives the spool, maintaining constant tension regardless of the line speed.

Active Pay Out Machine Parameter

| Model | QP630 active pay off machine | QP800 active pay off machine | QP1000 active pay off machine | QP1250 active pay off machine |

|---|---|---|---|---|

| Reel Size£¨mm) | OD400-630mm width 475mm, inner 56/80mm | OD630-800mm, width 600mm, inner 80mm | OD800-1000mm, width 750mm, inner 80mm | OD1000-1250mm, width 750mm, inner 80mm |

| Reel Size(inch) | OD24" -31" W:23" ID:3" | OD24" -31" W:23" ID:3" | OD31" -39" W:29" ID:3" | OD39" -49" W:29" ID:3" |

| wire diameter | 0.32-4MM | 0.5-15MM | 5-25MM | 5-30MM |

| pay off mode | active pay off | active pay off | active pay off | active pay off |

| machine Speed | 0-250m/min (Inverter adjustable speed) | 0-300m/min (Inverter adjustable speed) | 0-250m/min (Inverter adjustable speed) | 0-250m/min (Inverter adjustable speed) |

| Clamping Method: | hand crank clamping (or cylinder clamping) | hand crank clamping (or cylinder clamping) | hand crank clamping (or cylinder clamping) | hand crank clamping (or cylinder clamping) |

| pay off Motor | 2.2KW +RV90-1:7.5 electric screw lifting, upper and lower limit devices, safety | 4KW+ RV90-1:7.5 electric screw lifting, upper and lower limit devices, safety | 5.5KW+RV10-1:7.5 electric screw lifting, upper and lower limit devices, safety | 7.5KW+RV10-1:7.5 electric screw lifting, upper and lower limit devices, safety |

| Power supply | 380V, 3-phase, 50HZ Or customize | 380V, 3-phase, 50HZ Or customize | 380V, 3-phase, 50HZ Or customize | 380V, 3-phase, 50HZ Or customize |

| max load | 750kg | 1000kg | 1000kg | 1000kg |

| Equipment color | RAL5015 blue | RAL5015 blue | RAL5015 blue | RAL5015 blue |

| wire Storage rack | Vertical Tension Wire Storage Stand 1) Total height: 1.8 meters; 2) Storage capacity: Approximately 15 meters, wire storage reels ¦Õ250mm (4 sets + 3 sets); 3) Applicable wire diameter: 1-9mm multi-strand cores, copper wire 2.2-4mm 4) Guide roller material: POM plastic steel / hard-anodized aluminum rollers 5) Control method: Sensor outputs 0-10V voltage signal to regulate wire release speed | Vertical Tension Wire Storage Stand 1) Total height: 1.8 meters; 2) Storage capacity: Approximately 15 meters, wire storage reels¦Õ250mm (4 sets + 3 sets); 3) Applicable wire diameter: 1-9mm multi-strand cores, copper wire 2.2-4mm 4) Guide roller material: POM plastic steel / hard-anodized aluminum rollers 5) Control method: Sensor outputs 0-10V voltage signal to regulate wire release speed | Vertical Tension Wire Storage Stand 1) Total height: 1.8 meters; 2) Storage capacity: Approximately 15 meters, wire storage reels ¦Õ250mm (4 sets + 3 sets); 3) Applicable wire diameter: 1-9mm multi-strand cores, copper wire 2.2-4mm 4) Guide roller material: POM plastic steel / hard-anodized aluminum rollers 5) Control method: Sensor outputs 0-10V voltage signal to regulate wire release speed | Vertical Tension Wire Storage Stand 1) Total height: 1.8 meters; 2) Storage capacity: Approximately 15 meters, wire storage reels ¦Õ250mm (4 sets + 3 sets); 3) Applicable wire diameter: 1-9mm multi-strand cores, copper wire 2.2-4mm 4) Guide roller material: POM plastic steel / hard-anodized aluminum rollers 5) Control method: Sensor outputs 0-10V voltage signal to regulate wire release speed |

Active Pay Out Machine Application

QP Series Active Pay off Machine Advantage

1. Efficiency and Precision

The equipment uses a frequency converter to control the payout speed. Combined with a swing-arm design, a cylinder-controlled swing guide wheel, and a displacement sensor, it ensures precise payout, prevents cable accumulation and damage, and improves production efficiency.

2. Protecting Wire Quality

The active payout machine actively controls the payout process, eliminating problems such as wire core thinning and tangling, ensuring high wire quality throughout the production process. It is particularly suitable for coiling and reeling small square wires.

3. High Level of Automation

The equipment supports shaftless power payout, making reel loading and unloading simple, reducing manual intervention and further improving the automation level of the production line.

4. Optimized Structural Design

Some equipment features a vertical or horizontal payout frame design, which is compact and flexible, adapting to the needs of various production environments and enhancing the equipment’s practicality.

_副本-300x300.jpg)