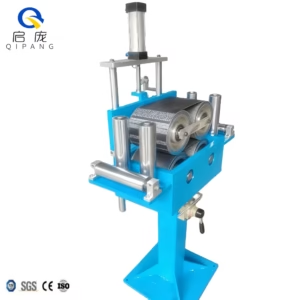

QP630mm active pay-off machine detail

1, dance wheel control tension

2.Clamping reel without shaft

3.Cylinder clamping saves manpower

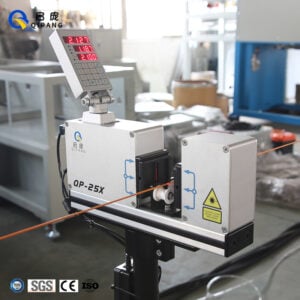

4.Control cabinet adjustment parameters

use: pay-off machine, take up machine,winder machine,Extruder, production line, rewinding machine,

Material used: copper and aluminum wire, PVC wire, optical fiber, pipe, fine wire, rope, braid, bag

QP630 Active Pay off Machine Parameter

| Active Pay Off Machine Specification | ||

|---|---|---|

| Reel Width (mm) | 300-475mm | 300-475mm |

| Reel Inner Hole (mm) | 56/80/127mm | 56/80/127 |

| Max. Loading Weight(kg) | 450KG | 600KG |

| Suitable Wire Diameter | 0.1-8mm | 0.1-12mm |

| Pay Off Speed | 0-300RPM | 0-400RPM |

| Pay Off Motor | 1.5KW+RV | 3KW+RV |

| Lifting Motor | 0.75KW+RV63 | 0.75KW+RV63 |

| Reel Clamping Type | Hand-cranked or cylinder | |

| Control mode | PID regulation control | |

| Braking Method | / | Electromagnetic braking |

| Quantity | 1+4+3+1 | 1+4+3+1 |

| Power Supply | Three-phase, 50Hz 380V | Three-phase, 50Hz 380V |

QP630mm active pay-off machine Drawing without lifting

QP630 Active Pay off Machine Advantage

1. Efficiency and Precision

The equipment uses a frequency converter to control the payout speed. Combined with a swing-arm design, a cylinder-controlled swing guide wheel, and a displacement sensor, it ensures precise payout, prevents cable accumulation and damage, and improves production efficiency.

2. Protecting Wire Quality

The active payout machine actively controls the payout process, eliminating problems such as wire core thinning and tangling, ensuring high wire quality throughout the production process. It is particularly suitable for coiling and reeling small square wires.

3. High Level of Automation

The equipment supports shaftless power payout, making reel loading and unloading simple, reducing manual intervention and further improving the automation level of the production line.

4. Optimized Structural Design

Some equipment features a vertical or horizontal payout frame design, which is compact and flexible, adapting to the needs of various production environments and enhancing the equipment’s practicality.

_副本-300x300.jpg)