The cable reeling and coiling machines is mainly applied in the wire and cable industry for coiling and bundling wires and cables:

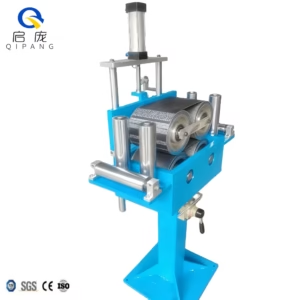

• Organize Cables and Wires: It winds various soft or hard conductor wires (such as copper wires, enamel – insulated wires, tinned wires, copper – clad steel wires, copper – clad aluminum wires, etc.) and electronic wires (like power cords, telephone wires, audio wires, video wires, automotive wires, network cables, etc.) into coils according to certain rules. This makes the wires and cables neatly arranged and aesthetically pleasing, facilitating subsequent transportation, storage, and usage.

• Improve Production Efficiency: Compared with manual coiling, the coiling machine has a high degree of automation and a fast take – up speed (for example, the take – up speed of some models can be adjusted from 0 to 300). It can significantly enhance production efficiency. Some models can even enable one person to complete multiple processes such as wire coiling, bundling, and plastic film packaging.

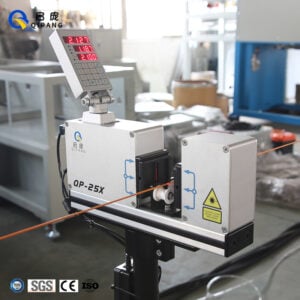

• Accurate Metering and Control: Equipped with a meter counter for accurate metering, it automatically stops when the set length is reached. This is convenient for coiling according to the specified length and also for controlling the usage and cost of wires and cables.

• Ensure Coiling Quality: Through the automatic coiling device, the coiling pitch is not affected by the wire diameter, and the coiling quality is stable, avoiding problems such as disordered and overlapping wires during the coiling process.

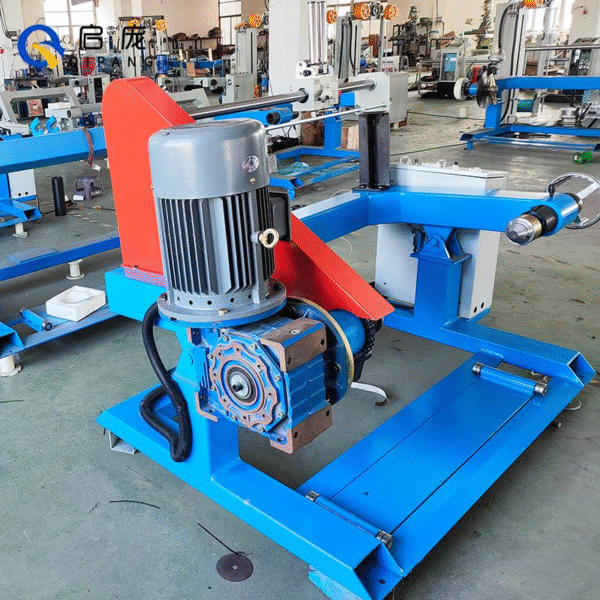

| Model | QPC500 |

|---|---|

| Wire Diameter | 0.5-25MM |

| spool size | OD200-500MM |

| coil size | Outside Dia .≤500mm Inner Dia. 120/140mm Width40-100mm |

| Take-up speed | 0-250RPM (customizable speed) |

| Wiring Mode | rolling ring drive |

| Load-Bearing | 100kg |

| Motor Power | 2.2KW |

| Voltage | three phase power 380v 50hz |

| machine Size | 1.32*1.32*1.52 m |

| weight | 280kg |

_副本-300x300.jpg)