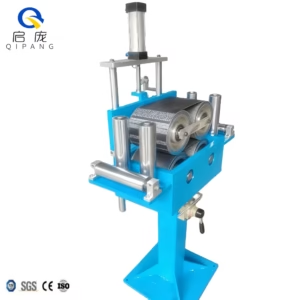

The machine adopts the whole frame moving structure, which enhances thecarrying capacity of the equipment. The wire keeps a straight line, the electriclifting and lifting are convenient to operate.Ball screw wire, suitable for different diameters, high precision.A layer of paper can be laid underneath.Uses: stranded, extruded, irradiated wire, new energy copper wire, flat wire,aluminum wire

Lifting mode: adopt electro lifting mode

Bobbin Clamping mode: 400W deceleration motor clamping

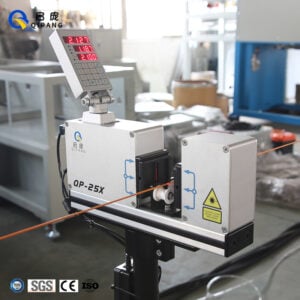

Take-up model: 0.75 kw 1500rpm Siemens AC servo motor drive, Speed and tension control can be achieved

Take-up torque: Max ~4600 N.m

The wire traversing adopts AC servo motor drive, ball screw traversing wire pitch:0~40mm, and sychronization with Take-up.

The device contains pneumatic brakes that can be used to brake rapidly during downtime.

Siemens S7-1200 PLC control, 7-inch touch screen control wiring traversig .wiring pitch can be set on the touch screen Main parts bearing use NSk

_副本-300x300.jpg)