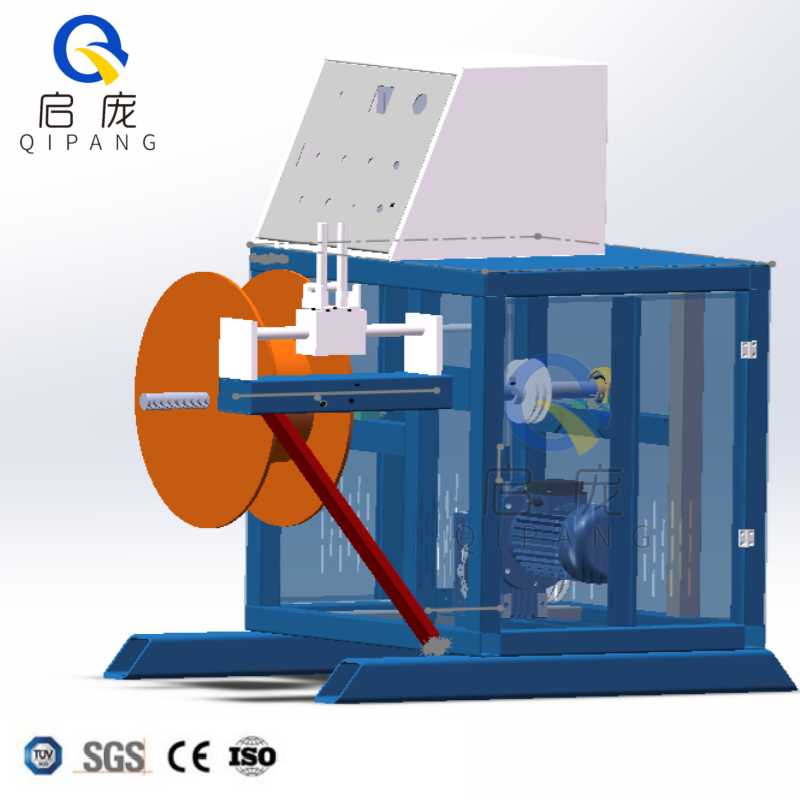

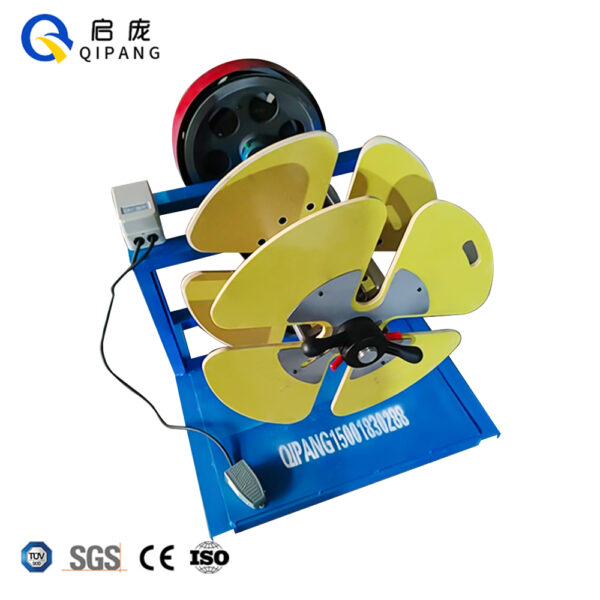

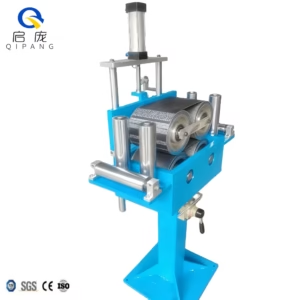

Shanghai Qipang is a leading enterprise specializing in the research, design, manufacturing, and sales of wire and cable rewinding equipment. Our automatic wire coil winding machine is specifically designed to efficiently wind materials such as wires, cables, copper wires, flat strips, ropes and so on into neat hollow coils. This significantly reduces transportation volume, lowers logistics costs, and enhances the overall value of the product. Durable and easy to operate, it is an indispensable asset for your modern production line.

A wire coil and reeling winding machine is a specialized piece of automated equipment designed to neatly and compactly wind flexible, linear materials—such as cables, wires, ropes, and hoses—into hollow coils (also known as spools or reels). Its primary purpose is to facilitate the storage, transportation, management, and subsequent processing of the product. Unlike traditional solid reels, the hollow coil structure saves material on the central core, thereby reducing the overall weight and cost.

| Model | QP500 | QPL500 | QP630 | QPL630 | ||

|---|---|---|---|---|---|---|

| Wire Diameter | 0.5-25MM | 0.5-25MM | 1-30MM | 1-30MM | ||

| coil size(mm) | Outer Dia .500mmInner Dia. 120/140/160/200mmWidth40-100mm | Outer Dia 500mmInner Dia. 120/140/160/200mmWidth40-100mm | Outer Dia 630mmInner Dia. 200/250/300mmWidth100-200mm | Outer Dia 630mmInner Dia. 200/250/300mmWidth100-200mm | ||

| coil size(inch) | Outer Dia .19.69″Inner Dia. 4.72″/5.51″/6.3″/7.87″Width1.57″-3.94″ | Outer Dia .19.69″Inner Dia. 4.72″/5.51″/6.3″/7.87″Width1.57″-3.94″ | Outer Dia 24.8″Inner Dia. 7.87″/9.84″/11.81″Width 3.94″-7.87″ | Outer Dia 24.8″Inner Dia. 7.87″/9.84″/11.81″Width 3.94″-7.87″ | ||

| Take-up speed | 0-250RPM (customizable speed) | 0-250RPM (customizable speed) | 0-250RPM (customizable speed) | 0-250RPM (customizable speed) | ||

| Wiring Mode | rolling ring drive | PLC servo wiring | rolling ring drive | PLC servo wiring | ||

| Load-Bearing | 200kg | 200kg | 200kg | 200kg | ||

| Motor Power | 1.5KW | 1.5KW | 2.2kw | 2.2kw | ||

| Voltage | 380v 50hz Support customization | 380v 50hz Support customization | 380v 50hz Support customization | 380v 50hz Support customization | ||

| machine Size | 1.32*1.32*1.52 m | 1.32*1.32*1.52 m | 1.57*1.05*1.5m | 1.57*1.05*1.5m | ||

| weight | 280kg | 280kg | 380kg | 380kg | ||

| advantage | With foot switch | With foot switch | With foot switch | With foot switch |

Wire Coil Winding Machine application

Coiling machines are widely used across various industries:

- Wire and Cable Industry: For winding power cables, communication cables, control cables, RF coaxial cables, and electronic wires into coils of fixed lengths, facilitating sales and installation.

- Fiber Optic Cable Industry: For the gentle and neat coiling of valuable and delicate fiber optic cables.

- Rope and Webbing Industry: For packaging various types of products such as nylon ropes, steel wires, safety belts, and webbing.

- Tubing Industry: For coiling flexible tubes and pipes, such as hoses and corrugated pipes.

Copper Wire Coil Winding Machine

Wire Coil Winding Machine FAQS

1. What Is The Weight Capacity Of The Wire Coiler Winding Machine?

The wire coiler winding machine can bear up to 100 kg.

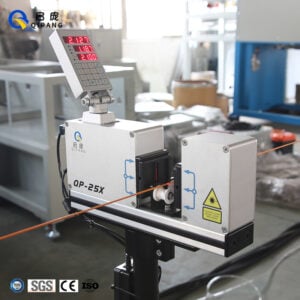

2. What Is The Adjustable Speed Of The Machine?

The adjustable speed is approximately 300m/min ; other rates can be customized.

3.Can This Machine Have A Plc?

This is possible. Our machine usually uses PLC (Programmable Logic Controller) or single-chip microcomputer, which is responsible for setting parameters such as winding length, winding speed, wiring width, and coordinating the automated operation of the entire machine.

4. Does The Machine Come With A Power Distribution Cabinet?

Yes, the machine has a power distribution cabinet with a power supply and frequency converter.

5. Are There Any Additional Features I Can Add To The Machine?

Yes, you can add a meter counter to set the number of meters to stop and alarm and a magnetic powder tension device to match the production line, ensuring constant speed and preventing wire strain.

.

_副本-300x300.jpg)