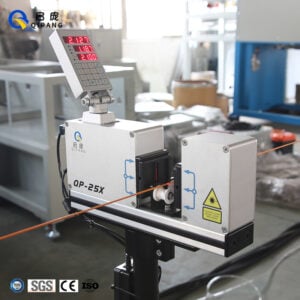

Shanghai Qipang is a leading enterprise specializing in the research, design, manufacturing, and sales of coiling and spooling take up machine. Our automatic wire coil winding machine is specifically designed to efficiently wind materials such as wires, cables, copper wires, flat strips, ropes and so on into neat hollow coils. This significantly reduces transportation volume, lowers logistics costs, and enhances the overall value of the product. Durable and easy to operate, it is an indispensable asset for your modern production line.

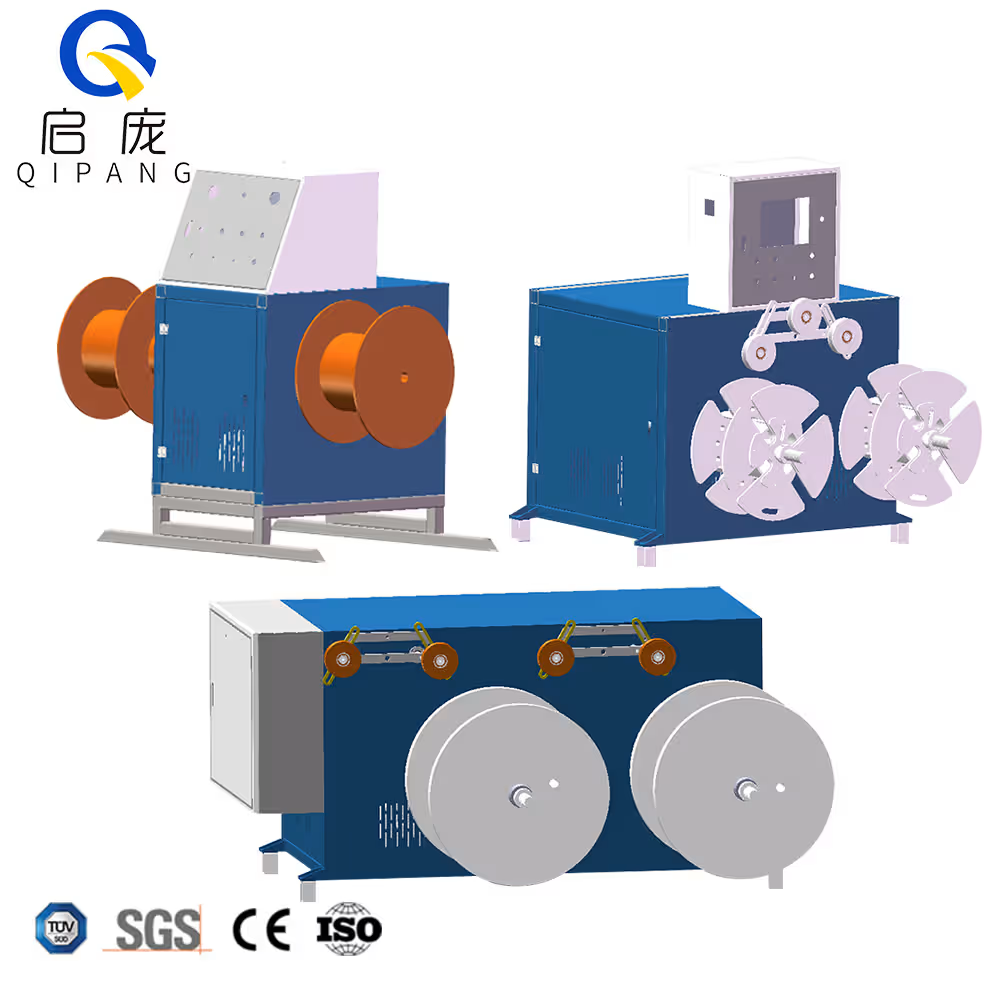

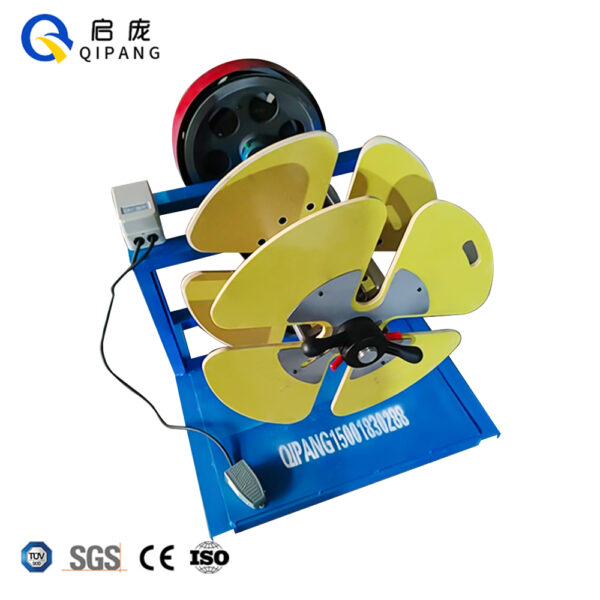

Dual-head coiling machines are specifically designed to address the frequent downtime for reel changes in wire and cable production, serving as key equipment for achieving continuous and efficient winding. With two winding stations operating alternately, they ensure seamless transition from one completed reel to another, maximizing the operational efficiency of the production line.

Dual Head Coiling Machine Parameter

| Model | QPX-630 | QPX-630L |

|---|---|---|

| Wiring Model | rolling ring drive | PLC servo traverse |

| Wire Diameter | 1-30mm soft cable/tube/rope | 1-30mm soft cable/tube/rope |

| Center Height | 450mm/650mm (630 spool/coil) | 450mm/650mm (630 spool/coil) |

| Machine Speed | 0-250 rpm or customizable | 0-250 rpm or customizable |

| Operating Mode | mechanical panel button operation | PLC, human-machine interface automatic control system, automatic setting of parameters |

| Spool Size | PN400-630mm,max width 475mm,bore56/80/127mm | PN400-630mm,max width 475mm,bore56/80/127mm |

| Coil Size | id120mm,adjustable width 35-100mm, 0d400mm or customizable | id120mm,adjustable width 35-100mm, 0d400mm or customizable |

| Spool Size Inch | outer dia5.75" - 24.80",max width 18.70",bore2.20"/3.15"/5.00" | outer dia5.75" - 24.80",max width 18.70",bore2.20"/3.15"/5.00" |

| Coil Size Inch | id 4.72",adjustable width 1.38" - 3.94" 0d15.75" or customizable | id 4.72",adjustable width 1.38" - 3.94" 0d15.75" or customizable |

| Connection Method | flange shaft diameter 40mm,shaft type (top cone),customizable | flange shaft diameter 40mm,shaft type (top cone),customizable |

| Load Capacity | 200KG single shaft | 200KG single shaft |

| Motor Power | 2.2kw/4kw+ reducer motor | 2.2kw/4kw+ reducer motor |

| Supply Power | 380v 50hz three-phase or customizable | 380v 50hz three-phase or customizable |

| Machine Color | RAL5015 blue, customizable | RAL5015 blue, customizable |

The parameters are for reference only.The final details will depend on the actual requirements of the customer!!

Dual Head Coiling Machine Application

Coiling machines are widely used across various industries:

- Wire and Cable Industry: For winding power cables, communication cables, control cables, RF coaxial cables, and electronic wires into coils of fixed lengths, facilitating sales and installation.

- Fiber Optic Cable Industry: For the gentle and neat coiling of valuable and delicate fiber optic cables.

- Rope and Webbing Industry: For packaging various types of products such as nylon ropes, steel wires, safety belts, and webbing.

- Tubing Industry: For coiling flexible tubes and pipes, such as hoses and corrugated pipes.

Dual Head Coiling Machine Designation

rolling ring drive wiring

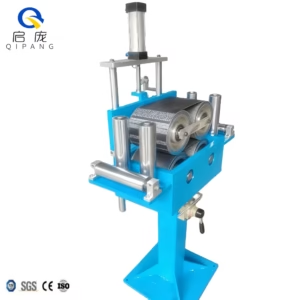

dual head coiling machine uses a traverse unit for wiring, featuring a simple and sturdy structure. The operation is intuitive and maintenance is convenient. It is highly suitable for standard production lines that require moderate wiring accuracy and pursue extremely high operational simplicity and equipment durability.

Servo wiring:

The machine is equipped with high-performance servo motors and precise screw rod guides. The wiring parameters can be directly set through a user-friendly touch screen. The wiring accuracy is high, the direction change is smooth, and it can perfectly adapt to different wire diameters and special process requirements. It is the best configuration for achieving high-quality automated production.

_副本-300x300.jpg)